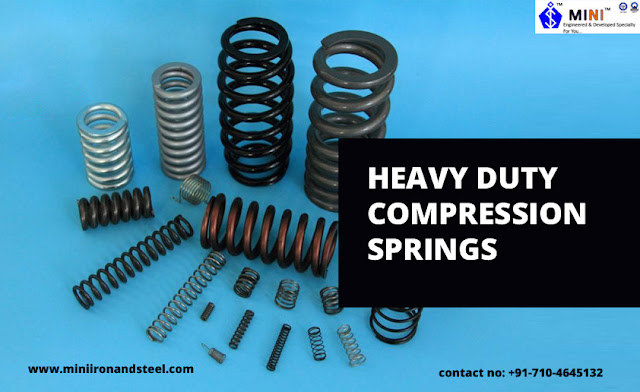

Heavy Duty Compression Springs and It’s Features

MISPL is a pioneer in manufacturing heavy duty compression springs . We believe in maintaining high quality with clear-cut design and compression. Heavy Duty Compression Springs are used to resist applied compression forces in a push mode. These springs come in various shapes like helical, rectangular, conical and other shapes. These springs are a function of many factors like outside diameter, wire diameter, free length, rate i.e. (lbs/in) as well as the spring material. The heavy duty compression spring production process has some problems which are a heavy load, low quality at normal temperature. That’s why softened wires are coiled at higher temperatures i.e. at around 900⁰C in an induction heating method where the cut material is introduced into a heating box i.e. the induction heating furnace. Then it is coiled at this temperature which leads to high-quality coiling. The heavy duty compression springs manufactured by Mini Iron and Steel can be availed by clients worldwid